|

|

|

|

|

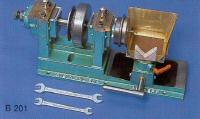

B201 Single head bruting or

grinding machine

B201 Single head bruting or

grinding machine

With two cupper bearings (oil-ring

lubrication), special eccentric

chuck, adjustable V-bloc, spanners

and receptable for swarf. |

B228 Single-phase motor,

220V+pulley, 1/4 hp, 4000 rpm

B228 Single-phase motor,

220V+pulley, 1/4 hp, 4000 rpm

B269 For double head,

220V+pulley, 1/3 hp, 3200

rpm

B269 For double head,

220V+pulley, 1/3 hp, 3200

rpm |

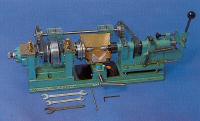

B260 Double head bruting or

grinding machine

B260 Double head bruting or

grinding machine

With 4 cupper bearings

(oil-lubrication), special

eccentric chuck step-pulleys and

belts to prevent slipping,

adjustable V-bloc, transmission,

spanners and receptacle. |

|

|

|

|

|

B268 3-phase,

220/380V+pulley, 3/4 hp, 3000 rpm,

for single & double head

B268 3-phase,

220/380V+pulley, 3/4 hp, 3000 rpm,

for single & double head |

B280 Concrete bruting

table

B280 Concrete bruting

table

For single or double head bruting

machine complete with lamp and

holder, concrete block+pedal and

electrical supplies |

B291 Camera security system

B291 Camera security system

- Multi purpose guard system

- Suitable for 4 cameras

- Auto-scanning

- Built-in audio system

- Very easy to install

- Complete : camera, monitor,

cable, brackets and all acc. |

|

|

|

|

|

B292 Stroboscope

B292 Stroboscope

This system is completely

automatic using a foot pedal.

Ideal for use with a camera

system. |

B295 Camera system for use

with diamond cutting machines

B295 Camera system for use

with diamond cutting machines

Designed to provide a perfect

image and optimal control of the

stone cutting process.

This camera system magnifies the

stone on the video display thanks

to special camera lenses. A

perfect combination, this camera

system together with the

stroboscope (detailed above)

provide from 15 to 20 x

magnification plus a still-effect

of the stone during the bruting

process.

Increase productivity.

No need to interrupt operation to

control the cutting process.

Improves quality noticeably. |

DH7500 Rubin DH electronic

bruter

DH7500 Rubin DH electronic

bruter

For bruting and polishing the

girdle without requiring

additional manipulation of the

stones. Supplied with :

- spanners - spare

pots and pins

- spare fuse - hammer |

|

|

|

|

|

DH7550 Iron bruting

table

DH7550 Iron bruting

table

For Ref DH7500 bruter.

Complete with single

lamp+holder |

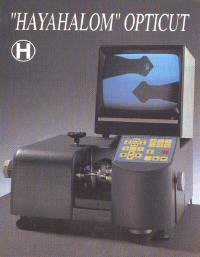

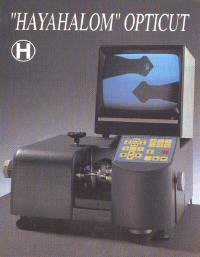

HA3000 Automatic electronic

diamond bruting machine

HA3000 Automatic electronic

diamond bruting machine

1. Automatic bruting &

diameter stop setting

2. Centering

3. Presser control between

stones

4. All stages of bruting are

computerised & can be

programmable in advance (choice

between coarse and fine

bruting)

5. Simple operation & quick

adaptation

6. Full visual display during all

stages of processing

7. complete control over all the

motors enabling choice of

bruting

8. Advance notification & self

halting of operation at the end of

the process

9. Excellent human engineering

with personal requirements

in mind

10. Modular construction (the

electronic & mechanical system

can be disconnected for continuous

maintenance)

11. A professional team of a

very high standard is available to

customers |

SH1000 Automatic bruting

machine SHANI I

SH1000 Automatic bruting

machine SHANI I

Excels at producing perfect round

cuts without beards

Brutes stones of any size - from

0.02 to 60 carats.

Extremely user-friendly operation

and short training period.

High productivity.

Training, in our plant, included

in the price.

Excellent service and repair

services for our customers.

When you purchase Shani I today,

you're assured of complete

compatibility with new features in

the future. |

|

|

|

|

|

SH2001 Automatic centering

device

SH2001 Automatic centering

device

State-of-the-art algorithm allows

the highest possible centering

accuracy in the shortest possible

time.

User-friendly software allows

operation by workers with no

special computer skills.

Centers stones on the holder

without need to center the holder

itself.

Small and compact.

Equipped with optical system that

includes zoom lenses to allow work

on a wide range of stone sizes

without need to change

objectives.

Allows communication with Shani

machines for automatic cutting

based on information gathered by

the centering system. |

|

|